The facility temperature pull down. A faster method of recovering refrigerant is to remove the refrigerant in its liquid form.

The CPR valve is now properly set.

Hot pull down refrigeration. Hot pull down is a term usually used in the commercial refrigeration industry when discussing a higher than normal heat load. Usually during initial startup. Special controls or monitoring are required to prevent compressor overload shutdown.

A method for operating a refrigeration system for a container to pull down the temperature of cargo from ambient to a predetermined set-point temperature and a system employing the method. It is basically heat that need to be removed from a refrigerated product to reduce its temperature to desired level. Load is calculated using this relation.

Space Temperature If you need more details refer to Principles of Refrigeration. For example in a particular refrigerator cold room if you put apples which are at 20 DegC if it takes 12 hours to bring down temperature of the apples to 2 DegC then 12 hours is the pull down time. It is an important factor in designing a refrigeration system.

When a piece of refrigeration equipment is in hot pull down it cannot be expected to abide by the typical DTD or superheat rules and must be allowed to get near the design box temperature before fine adjustments are made to the charge TXV superheat settings or to the EPR Evaporator Pressure Regulator if there is one. Boot strap refrigeration or Air refrigeration cycle is a refrigeration cycle that use air as a working fluid and is often incurred in the Aircrafts. The range of temperature pressure and speed values of air that exists in the upper atmosphere the flying region of Aircraft are not suitable for human comfort.

The facility temperature pull down. The first stage of the temperature reduction should be from ambient to 35 degrees F at whatever rate of reduction is achievable with the refrigeration system. The room should then be held at that temperature until it is dry.

Finishes are especially subject to damage when temperatures are lowered rapidly. The condenser coil of the refrigeration system removes heat from the system. Its not unusual to find condensers located in enclosed spaces or spaces with inadequate air flow to remove heat from the space.

The temperature around the compressor rises resulting in higher head pressure for the compressor which again increases compressor power. A hot pull down is when _____. There is excess ice on the evaporator the condenser contains an excess amount of liquid refrigerant the flow of refrigerant to the evaporator is reduced the load on the evaporator produces a suction pressure that increases the load on the compressor.

The CPR valve is now properly set. Another practical use for these refrigeration valves is found on hot gas defrost systems. The CPR valve helps disperse any liquid refrigerant that may flood back from the evaporator after defrost.

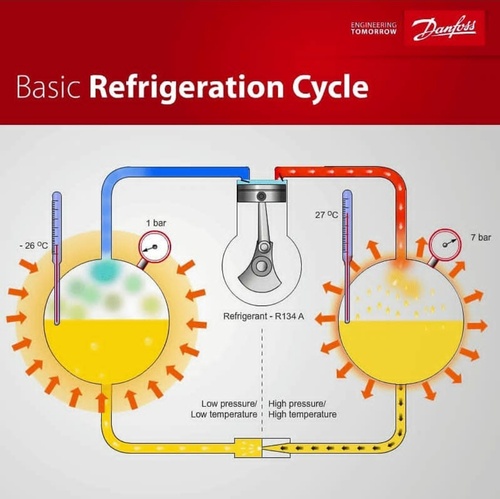

I always installed a CPR valve on freezer cases it. Refrigerants evaporate or boil at much lower temperatures than water which permits them to extract heat at a more rapid rate than the water on your finger. Refrigeration system fundamental components.

The job of the refrigeration cycle is to remove unwanted heat from one place and discharge it into another. Continue on down in stages and give the room time to equalize. If you rush it you stand a chance of buckling the floors.

I had one large cooler in Houston the we tried to pull down in August. It took it the better part of 4 weeks to dry the place out to the point we could pull on down to 35 dF room. The coils had water literally pouring off.

A refrigeration system that continuously runs under high-load conditions hot pull downs would most likely use a thermostatic expansion valve with a vapor charged thermal bulb assembly. The defrost heaters are used to melt accumulated frost off the evaporator coil surfaces and warm the drain pan to allow the defrost condensate to exit down the drain line without refreezing in the pan. A defrost termination control may be used to end the defrost period based on temperature.

Because of the heaters placement along the edge of the refrigerator cabinet it sometimes made the refrigerator door slightly hot to the touch when the heater was switched on. If you have an older refrigerator with this moisture-prevention system switch off your heater when you notice the temperature of your refrigerator increasing. If the system has 15 or more pounds of refrigerant this will be your faster option.

The more refrigerant the system holds the more time youll save. Using an inline sight glass during push-pull recovery will allow you to determine when the liquid flow has stopped visually. The first is the Recycling Pump Down circuit.

The method of pump down is still the same using a LPS and solenoid valve. However if on the off cycle refrigerant is able to creep by internally leaking solenoid valves or compressor valve plates this will. To test to see if your fridge has a defrost issue 1 Unplug your refrigerator 2 Leave the freezer door open for at least 12 hours 3 Be sure floor of the freezer is no longer cold to touch 4 Plug the refrigerator back in 5 If the fridge seems to be working properly about 30 to 45 minutes after plugging it in it is probably a defrost issue causing your problem.

There are several methods that can be used to recover refrigerant from a system. The most common is the vapor recovery method. A faster method of recovering refrigerant is to remove the refrigerant in its liquid form.

One method of recovering liquid refrigerant is the push-pull method.