For these applications the Klingelnberg Zyklo-Palloid tool system provides individual solutions with AMK blades made from HSS or holders equipped with carbide cutting plates for. PHOENIX 280C280CX Bevel Gear Cutting Machine users now can reduce cycle times by as much as 35 on the production of bevel gears and pinions up to 280 mm.

Patent 725328 and US.

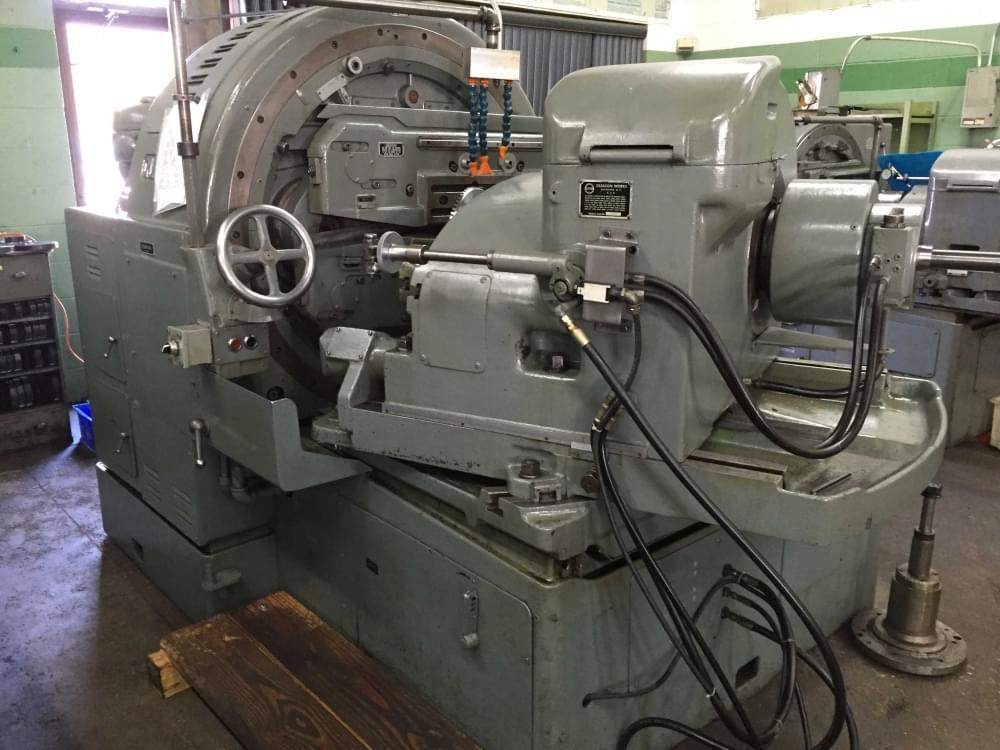

Gleason bevel gear cutting machine. Cutting Phoenix 280C 280CX - Cutting of Automotive and Small Truck Sized Bevel Gears Phoenix 600HC - Fast and Economical Production of Truck Sized Bevel Gears. Gleasons proprietary UnimillTM process enables users of Gleason Phoenix Cutting Machines to manufacture single or small lots of bevel gears employing universal cutters for highly flexible on-demand manufacturing and efficient prototype work. PHOENIX 280C280CX Bevel Gear Cutting Machine users now can reduce cycle times by as much as 35 on the production of bevel gears and pinions up to 280 mm.

Phoenix 280C 280CX - Cutting of Automotive and Small Truck Sized Bevel Gears The Phoenix Bevel Gear Cutting Machines are the most productive in their class with cutting cycle times significantly reduced. The 280CX is a highly automated solution for automotive and other gear manufacturers seeking efficient high volume production. ITALGEAR is equipped with increasingly precise and complex machines for Gear Cutting Machines in particular Gleason Gears Bevel Gears Cylindrical Gears.

Methods on Gleason machines. Many of the bevel gears that have been produced in Europe after 1945 on non-Gleason machines were manufactured with newly developed methods from the Swiss com- pany Oerlikon-Bührle. The so-called N and G methods from Oerlikon were continuous indexing cutting methods Refs.

The first modern face hobbing pro-cess based on machines with cutter. 16 spiral bevel gear generator is a heavy duty finishing machine that employs a cutter of the facemill type. The cutter acts as a tooth in a gear.

The first known gear cutting machine was developed by Juanelo Torian 1501 1575. He was able to produce up to three gears per day on his hand-powered machine using cutting tools that were nothing more than rotary files Ref. In 1910 a machine was invented for cutting spiral bevel teeth with face hob cutters using the continuous index process.

In 1913 a process and machine were. In single and small series customers demand tools that can be employed universally for the production of bevel gears with different modules while at the same time offering high productivity and low tool costs. For these applications the Klingelnberg Zyklo-Palloid tool system provides individual solutions with AMK blades made from HSS or holders equipped with carbide cutting plates for.

Bevel Gear Cutting Machines Phoenix. Of machines from Gleason metrology Systems. 7 Gear Manufacturing Tools Pentac Plus Cutter System For face hobbing and face milling on the latest CNC machines at optimum speeds and feeds.

Pentac Plus RT Radially Truable Cutter System The ideal solution for todays medium to high volume face hobbing and face milling appli. Twin Blade Coniflex Cutters for Gleason 14 Different styles used to generate straight bevel gears in either low or medium volumes. Gears cut by these tools can be crowned in a lengthwise direction.

We have Spiral Bevel Gear Generators Straight Bevel Gear Genrators Hypoid Bevel Gear Generators Bevel Gear Cutter Sharpeners Bevel Gear Universal Testers Lappers etc. We have machines of many manufacturers including Gleason Oerlikon Klingelnberg WMW etc. We can offer the following machines.

A wide variety of gleason bevel gear cutting machine options are available to you such as none. You can also choose from manufacturing plant energy mining and construction works gleason bevel gear cutting machine as well as from 15 years 6 months. 400 mm gear width.

Pinion diameter - max. 254 mm axial cross angle. 90 Â total power requirement.

15 kW weight of the machine ca. T dimensions of the machine ca. M This machine is very suitable for precision production testing of spiral and hypoid bevel gears with shaft angle 90Â.

The gear spindle is vertical and the pinion spindle is horizontal. Gleason Heller 5-Axis Machining with uP Gear Technology on CP 4000For additional information visit. After engineers at Packard developed spiral bevel gears Gleason pioneered the machine tools to mass-produce them with automotive differentials being the primary market.

Packard and Gleason settled an infringement lawsuit regarding Packards patents US. Patent 725328 and US. Patent 1209682 and Gleasons patent US.