Capacitive sensors from MicroSense offer the lowest noise performance of any commercially available capacitive sensor achieving nanometer and even picometer resolution. Shield drivers are included in capacitive-sensor interface devices and specialized microcontrollers.

FDC1004 features active shield drivers which can reduce EMI interference and help focus the sensing field of a capacitive sensor.

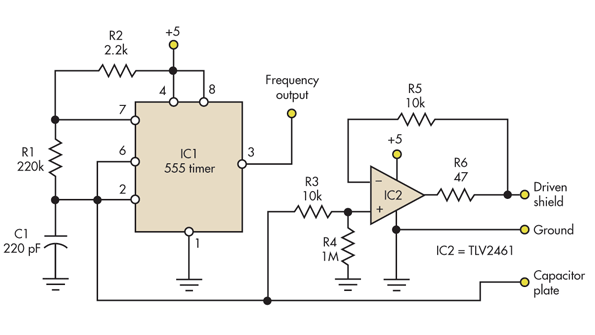

Driven shield capacitive sensor. Driven Shield Enables Large-Area Capacitive Sensor 1. In this large-area capacitive sensor C1 and any parallel capacitance set the frequency of the 555 astable. In the constructed sensor a double-sided printed-circuit board PCB has one.

Capacitive sensors used for proximity sensing and collision avoidance are generally known. However such sensors do not adequately control stray capacitance and consequently do not perform with an adequate range and sensitivity for many applications such as docking and berthing in outer space. Patent 5166679 entitled Driven Shielding Capacitive Proximity Sensor John M.

Driven Shield Drives shield electrode with a sequence of DC levels synchronized to the sensor measurement Requires a dedicated shield electrode Reduces or eliminates loading of sensors due to capacitance with neighbors Rear shield prevents touch from behind Improved water tolerance. A conductive shield that is disposed near the sensor wherein a signal is driven on the shield that is similar to the signal induced on the sensor thereby reducing stray capacitances and. Using a driven shield requires use of a coaxial cable for each capacitive sensor and added electronics to drive each shield.

This adds significant cost and bulk when there are multiple sensors. Moving the sensing circuitry local to the sensor itself whether you use a microcontroler or dedicated capacitive sensing IC costs less than even a. NASA used this driven-shield idea in a large-area capacitive sensor two decades ago.

In this large-area capacitive sensor C1 and any parallel capacitance set the frequency of the 555 astable multivibrator IC1 while IC2 buffers the voltage at the capacitor to drive the shield plate. A capacity type proximity sensor comprised of a capacitance type sensor a capacitance type reference and two independent and mutually opposing driven shields respectively adjacent the sensor and. FDC1004 features active shield drivers which can reduce EMI interference and help focus the sensing field of a capacitive sensor.

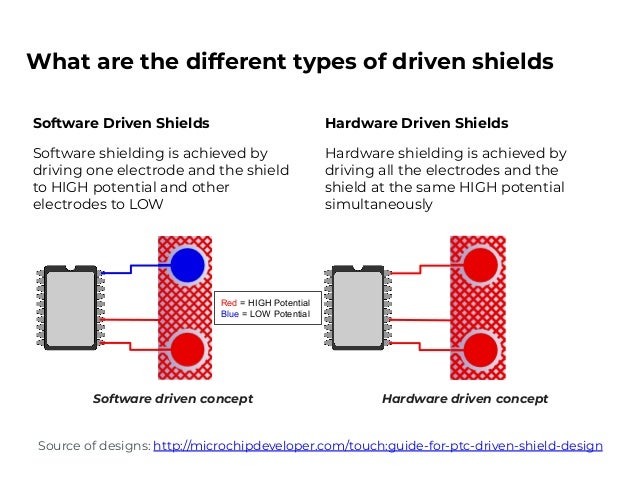

This application note introduces the concept of active shielding use cases for how shielding can help mitigate parasitic and environmental interference factors and how to implement it with the FDC1004 in a. In capacitive touch sensors the term shield usually means a conductive layer that prevents capacitive coupling of an external source to the capacitive touch sensor with the shield. Most common types of conductive layers consist of solid or hatched planes in close proximity to the sensing.

Using a driven shield requires use of a coaxial cable for each capacitive sensor and added electronics to drive each shield. This adds significant cost and bulk when there are multiple sensors. Capacitive Sensors 2 Surround this sensor with appropriate guard or shield electrodes to handle stray capacitance and crosstalk from other circuits Calculate sensor capacitance stray capacitance and output signal swing Specify transfer function like Eo C area-linear Eo 1C spacing-linear.

Precision Capacitive Sensors for Accurate Position Measurement Non-contact Position Measurement with High Resolution over Short Ranges. Capacitive sensors from MicroSense offer the lowest noise performance of any commercially available capacitive sensor achieving nanometer and even picometer resolution. Several types of sensors are available - these application specific capacitive position sensors.

A capacitive proximity sensing 18 element backed by a reflector driven at the same voltage as and in phase with the sensor is used to reflect the field lines away from a grounded robot arm 16 towards an intruding object 20 thus dramatically increasing the sensors 18 range and sensitivity. Doppler effect inductive and capacitive. Each method has its own benefits and limitations.

Capacitive sensing method is detecting the change of capacitance on the sensor due to users touch or proximity. For the Microchip solution a sensor can be any conductive material connected to a pin on a PIC MCU RightTouch or mTouch turnkey device. The shield driver is an active signal output that is driven at the same voltage potential same waveform as the sensor input so there is no potential difference and thus no capacitance between the shield and sensor input.

Any external interference will couple the shield signal with minimal interaction with the sensor signal. A conductive shield that is disposed near the sensor wherein a signal is driven on the shield that is similar to the signal induced on the sensor thereby reducing stray capacitances and protecting t. Login Sign up Search Expert Search.

US PatentsApps Other SEARCH. TOOLS RESOURCES Title. DRIVEN SHIELD FOR CAPACITIVE TOUCHPADS.

Shield drivers are included in capacitive-sensor interface devices and specialized microcontrollers. In case of PTC sensor measurement is sequential. So Y0 and Y2 sensors in your design cannot be acquired in parallel.

For using driven shield with PTC you will have to use the opamp based design as mentioned under Driven shields in the application note Secrets of Successful QTouch Design.