Either the work roll or the back-up roll is driven depending on customer requirements. Three roll feeder assy.

Delivery tension reel 8.

4 hi cold rolling mill process. YOGIJI DIGI sees itself as an AUTHORITY IN COLD ROLLINGWe have engineered and installed wide range of cold rolling mills skin pass mills as well as bonding. The 4-high mill is equipped with positive and negative work roll bending in order to influence the shape and the flatness of the strip. Either the work roll or the back-up roll is driven depending on customer requirements.

The diameter of the 4-high work rolls amounts to approximately 14 in relation to the barrel length. This type of rolling mill is mainly used in offline applications for cold rolling of soft and. Cold rolling on a 4 hi reversible mill 1.

A brief on Cold Rolling of Steel in a 4 Hi Mill By Hussam Adeni Lubricant Specialist 2. Cold rolling of Steel strips The raw material for Cold rolling is typically a Hot rolled coil HRC. At the CR Mill it undergoes the following operations.

Raw material Hot rolled coils slitting 2. Pickling or acid wash with Hydrochloric Acid 3. Short term rust protection with emulsion 5.

Sizing to get idea coil OD. Manufacturerssuppliers of ss cold rolled coil manufacturing process of ss coil ss coil is mde by cold rollig mill. The main steps are given below first annealing first pickling rolling process conventional discontinuous rolling continuous rolling construction and working of 4 hi cold rolling mills final pickling final annealing skin pass rollingiempering finishing testing packing marking market survey demand.

AGC 4-hi rolling mill control accuracy especially suitable for high precision cold-rolled strip production. Production line process Front coilerUnloading carMachine front device 4-hi main rolling mil Machine after the deviceAfter the coiler Unloading caraccording demands to arrange the uncoiler Starting straightening machine etc. Composition of a 4-hi cold rolling mill Rollers.

One pair of work rollersupper work roller and lower work roller and one pair of backup rollersone upper backup roller and one lower backup roller. Two stands pair well and are connected oppositely To process the pair of stands wholly manually shovel the surface to be flat with sliding plate at window. Be produced by 20 Hi rolling mill whereas the more thick sheets can be produced by 4 Hi or 6 Hi rolling mill 4 to 10 microns.

The arran gement of the rolls i n the rolling m ill decides the spee. Equipment details crm-1 consists following equipments. Coil storage saddle 2.

Coil car 1 2 3 3. Pay off reel 4. Three roll feeder assy.

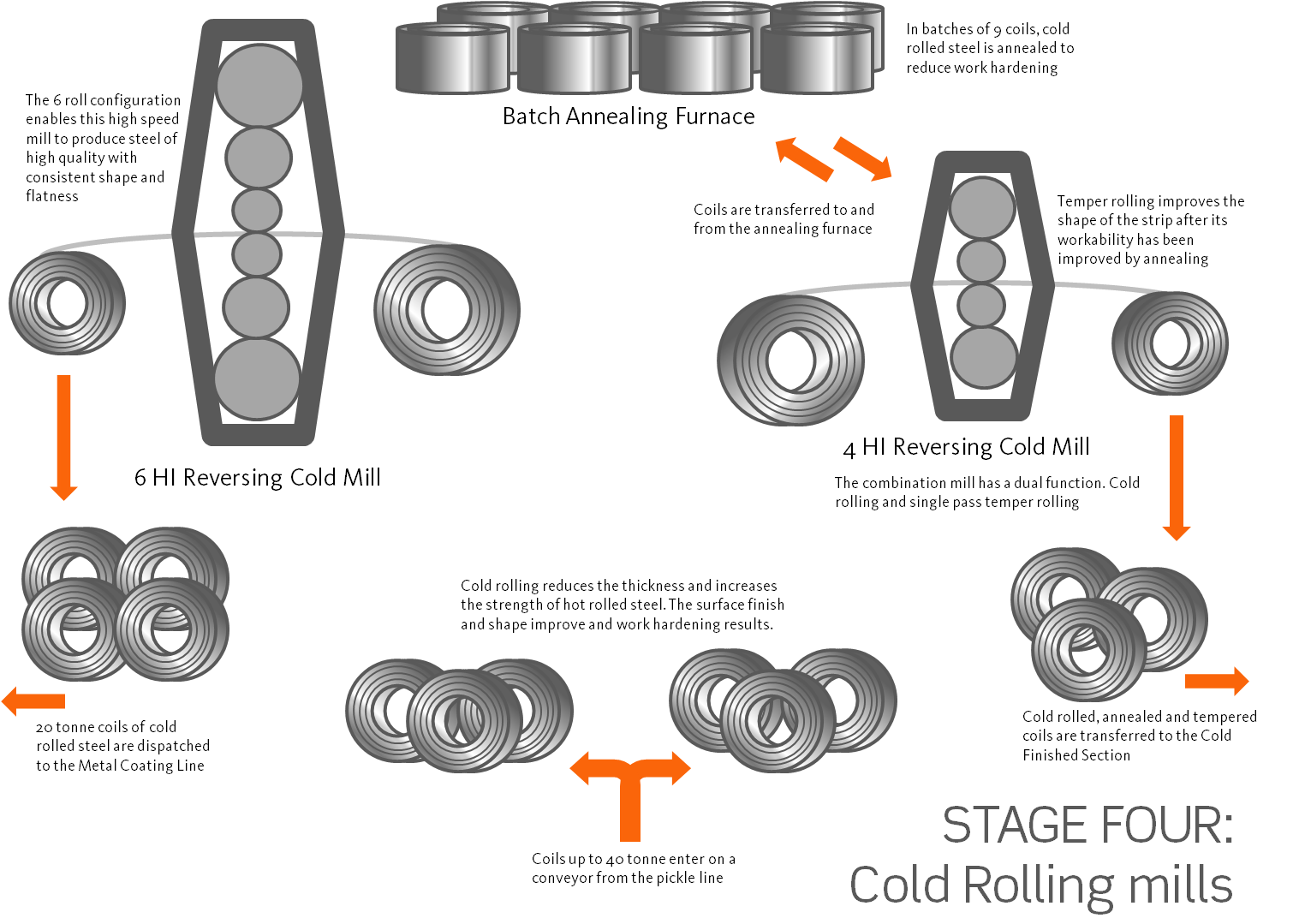

Entry tension reel 6. 6 high reversible mill 7. Delivery tension reel 8.

Roll changing car rcc 6 8. Pay off reel snubber roll mendrel 7 9. A walkthrough video with voiceover explaining the latest features of YOGIJIDIGIs 6 HI Cold Rolling MillsYOGIJI DIGI sees itself as an AUTHORITY IN COLD R.

To minimize the roll diameter a four-high or cluster mill is used. A small roll diameter is advantageous because less roll is in contact with the material which results in a lower force and power requirement. The problem with a small roll is a reduction of stiffness which is overcome using backup rolls.

These backup rolls are larger and contact the back side of the smaller rolls. A four-high mill has. A 4-high rolling mill can be a small mill or a stand-alone high torque high reduction mill.

A typical reversing mill has a quick change roll system. Four-high mills can be equipped with roll bend and shape control a precision consistent product. Old 4-high cold rolling mills can be upgraded.

A novel customized Cold Rolling Mill designedsupplied commissioned as per customers specific requirementYOGIJI DIGI sees itself as an AUTHORITY IN COLD. That produce high rate of production more than rate of production more than two high roll methods. This three high rolling mill used to billet rolling blooming or finish rolling.

4 high rolling mill. 4 high rolling mill diagram. That rolling mill having four horizontal rolls which two rolls are small diameter and another two rolls are larger diameter.

It will be arranged with one over other as shown in. Depending on the product mix and quality demands Primetals Technologies offers 6-high or 4-high mill stands to meet the respective product and customer requirements. In reversing cold mills the tension reels are placed on both ends of a single- or two-mill-stand arrangement.

Due to the reversing rolling passes production efficiency is lower than that of a tandem mill. However because the rolling parameters can be quickly changed for each coil reversing cold mills. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators.

Four High Rolling Mills. In this type of mill there are four parallel rolls one by another. In this operation the rotation of the first and the fourth rolls take place in the opposite direction of the second and the third rolls.

The second and third rolls are smaller to provide rigidity in necessity. So those are known as back up rolls. It is used in the hot rolling process of the armor and in the cold rolling process.